|

Hot Weather's Here!

How are your cows feeling?. . . . How are they milking? |

||

|

For as laid-back as dairy cattle are, it doesn’t take much to get them stressed—heat stressed that is.

Lactating dairy cows produce metabolic heat at roughly the same rate as sixteen

100-watt light bulbs. That’s

a lot of heat and it needs to be dissipated if internal body temperature

is to remain around the normal 101.5 F. The warmer the surrounding environment, the harder it is to

lose that heat and the greater a cow’s thermal discomfort. The more uncomfortable she feels, the more apt she is to

invoke coping mechanisms to help “keep her cool”.

Of greatest concern to dairy producers is her tendency to reduce

feed intake, since lower milk yield is a likely result.

Dry matter intake (DMI) decreases by about 0.17 lb for every 1

degree above rise in environmental temperature over 68 F--and every 1 lb

drop in DMI generally translates into a 2-lb loss in milk yield ((NRC, (1).

Other research indicates that milk yield will drop about 0.6 lb/day for every one unit rise

in THI over 70 ((Johnson, 1963) (2). Milk yield in severely heat stressed cows may drop by as much as 25 to 30%.

Heat stress seriously impacts reproduction, too.

One Florida study demonstrated that conception rate dropped from

about 52% during cool months to 30% for the hot months of June through

September. Conception rate in

commercial dairies has been known to decline to less than 10% during hot

weather. Even when conception

is successful, heat stress can reduce calf birth weight, and reduce milk

yield during the subsequent lactation (3).

Further, heat stress compromises cows’ immune function and can cause a

drop in milk fat content (1).

|

||

.

| More To Heat Stress Than Just Air Temperature | ||||

| . | ||||

|

Effectively controlling dairy heat stress starts with an accurate

assessment of how your cows are feeling over the course of day.

Tracking air temperature is a good start, but cows, like all

animals (including humans) respond physiologically and behaviorally to

more than just air temperature. Humidity,

air speed, evaporation, conduction to lying surfaces and radiant heat

exchange with the surroundings all factor into a cow’s feeling of

thermal comfort. |

||||

| . | ||||

|

Accurately accounting for the combined influence of all of these

factors is beyond our current scientific capability.

But you can get a reasonable assessment of cow heat stress with the

Temperature- Humidity Index (THI).

By measuring temperature and percent relative humidity and

cross-referencing these values on the THI chart (Fig. 1) you’ll know

what level of heat stress your cows are experiencing:

No stress, Mild, Medium or Severe. |

|

|||

| The chart takes into account the influence of relative humidity on how a cow feels at a given air temperature. The higher the humidity, the slower the rate of evaporative heat loss from the hide and respiratory tract, hence the warmer a cow feels. Low temps and low humidities are most comfortable and high temps coinciding with high humidities are most stressful. | ||||

| . | ||||

| Dairy cows begin to suffer Mild heat stress whenever the THI reaches 72 or higher (Combs, 1996(6)). Moderate stress occurs with THI’s of 80 and above, resulting in rapid shallow breathing, profuse sweating, and reduction in milk yield that can exceed 10%. THI’s of 90 and above constitute Severe heat stress, indicated by open mouth panting, elevated body temperature, and as much as a 25% decrease in milk yield. Remember, THI is not air temperature, but air temperature adjusted for the effect of humidity. | ||||

| Data-Logging THI | |||

| Without good temperature and humidity data, the THI isn’t particularly useful to dairy producers trying to get an accurate picture of heat stress in their herds over time. That’s where data logging comes in. | |||

| Small, battery-operated data loggers are now available for tracking temperature and humidity in dairy facilities. These units are self-contained. They need no permanent connection to a power supply or a computer in order to work. Temp and humidity data, recorded every few minutes over several days, can be downloaded to a PC and viewed as a graph or in table form. | |||

|

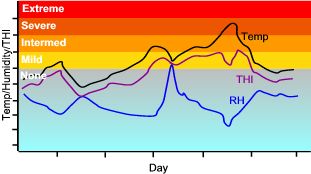

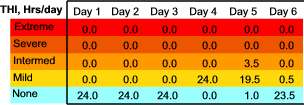

A new THI Logger System

automatically converts temp/humidity data into dairy THI numbers and

summarizes them in a color-coded graph and daily summary of the hours per day that cows were in the

various THI heat- stress categories: No

Stress, Mild, Intermediate, Severe, and Extreme.

Monitoring THI around the clock gives you a

much more accurate picture of when, how long, and to what

degree your cows are heat-stressed. |

|

||

|

|||

.

| Adding to THI | ||

| . | ||

| In an effort to improve the accuracy of estimating cow thermal comfort, researchers at the University of Nebraska (7) are making progress in expanding the principle of THI to include effects of other environmental factors. Using panting scores as a measure of heat stress, they estimate that THI drops 1.1 units for every 1 mph increase in wind speed. | ||

| . | ||

|

From this, one could conclude that using stirring fans to produce a 3 mph breeze through a free-stall or tie-stall barn would

effectively reduce heat stress by 3.3 THI units and possibly increase milk

yield by nearly 2 lb/cow /day.

Information such as the above is useful to dairy managers in a couple of ways: (1) a guide for determining how cost-effective cooling systems such as stir fans can be, and (2) deciding the best temperature at which stir fans should come on. |

||

| . |  Temp/Humidity/

Air-Speed Meter

Temp/Humidity/

Air-Speed Meter |

|

| Using the above approach to systematically judge cow thermal comfort on your farm requires nothing more than a THI chart and an inexpensive hand-held meter for measuring air temperature, humidity, and air speed all in one unit. | ||

.

| Combating Heat Stress | ||||

| . | ||||

|

Management strategies for controlling heat stress in dairy cattle are well

covered in various extension publications--many of which are listed in Info Resources section below.

Dairy Specialists at Mississippi State University suggest

these nine points (8): |

||||

| . | ||||

| 1) | Provide shade to

protect cows from direct sunlight. |

|||

| . | ||||

| 2) | Take advantage of

evaporative cooling. The

combination of air movement (stirring fans or tunnel ventilation) and

sprinklers appears to be the most effective cooling method.

|

|||

| . | ||||

| 3) | Feed during the

cooler period of the day when cows are more comfortable. |

|||

| . | ||||

| 4) | Increase the number of feedings to insure freshness and

promote greater intake. |

|||

| . | ||||

| 5) | Adjust the ration to

provide adequate protein, energy, minerals, and vitamins-giving

consideration to the lower dry matter intake.

Supplemental fat such as oilseeds should be used. |

|||

| . | ||||

| 6) | Feed high quality

forages. |

|||

| . | ||||

| 7) | Increase the level of potassium to 1.3-1.5 percent of total ration dry matter; sodium to 0.35-0.40 percent; magnesium to 0.35 percent. | |||

| . | ||||

| 8) | Balance the

degradable and nondegradable protein, especially that fed to high

producing cows. |

|||

| . | ||||

| 9) | Provide the lactating herd unlimited access to clean, fresh water. | |||

.

| The Latest on Heat-Stress Abatement | |||

| . | |||

| Tunnel Ventilation | |||

| More

widely adopted in the eastern US than in parts west at the present time,

tunnel ventilation helps keep cows cool by providing a fan-driven breeze

at rates as high as 600 ft/min (6.8 mph). Research suggests that air

movement at a rate this high may drop THI by as much as THI 7.5 units (7).

Fan banks in one endwall

operate to draw fresh air in large air inlets located on the opposing

endwall thus. Large volumes of high-velocity air moves through the

barn in a linear or "tunnel" fashion. Evaporative systems

(sprinklers, foggers, or pads) may be incorporated into the design to

provide even greater cooling

benefit.

A carry-over from the poultry and pork industry, tunnel ventilation is proving its worth in dairy units, too. Excellent information on the principles of tunnel ventilation, economics, and design considerations may be found at the Cornell University Pro-Dairy website (9) . . |

|||

| TIV (Time-Integrated Variable Control) | |||

|

Considerable time

is needed for cows to dissipate body heat accumulated over the course of a

warm day--hours longer than the time it takes for the surrounding air

temperature to drop off in the late afternoon and evening.

Traditional ventilation controllers tend to reduce ventilation rates too

quickly during this time of day, which can hinder cow heat loss. The

new TIV (time-integrated variable) ventilation controller tracks air

temperature during the day and when heat stress occurs, keeps ventilation

rates elevated and cooling systems operating longer into the evening to

help cows cool off. A

TIV controller is applicable for use in free stall and tie stall barns

with mechanical (tunnel) ventilation systems and supplemental cooling

systems. It can be used to control natural (curtain) or tunnel ventilation

systems.

The TIV ventilation controller is licensed for manufacture by Thevco

Electronics, Quebec, Canada and is available from ventilation dealers

carrying the Thevco line (eg., Aerotech).

|

|||

| HVLS Fans (High Volume, Low Speed) | |||

|

New to the dairy market in the last couple of years are the high

volume low speed (HVLS) fans that put a lot of air across cows for

considerably less electricity than traditional stir fans.

Commonly referred

to as “big ass fans” HVLS paddle fans have 10 and measure up to 24

feet in diameter. They are

driven by a 3/4 to 1 HP motor at an rpm as low as 50.

A recent Wisconsin

field study (10) indicates

that dairies are generally placing 24-ft diameter HVLS fans in a single row over the center drive

lane in 4-row or 6-row free stall barns.

In 3-row barns, the fans are placed over the centerline of the free

stall platforms. Fans within a row are

spaced 60 to 70 feet apart o.c. and are mounted at a height of 16 to 18 ft off the floor.

The effective stall coverage

appears

to be 45 stalls/fan in a 3-row barn, 53 stalls/fan in a 4-row, and 88

stalls/fan in a 6-row barn. The

fan systems, installed as described, put approximately 200-300 fpm

airspeed over the feed bunk in a 4 or 6 row barn, with a low-end velocity

of slightly less than 100 fpm at the outer row of free stalls.

The 24 ft diameter fans cost approximately $4000 to $5000 each, including controls and installation labor. Based on an electricity charge of $.07/kWh, the cost to continuously operate a 24 ft HVLS fan is approximately $1/fan/day, compared to nearly $18/day for operating a bank of traditional stir fans moving the same volume of air.

|

|

||

| Stirring Fan/Fogger Systems | |||

|

Fog or mist systems (having very fine sprays) are the evaporative cooling method of choice in the air southwest United States. Such systems cool the air, which in turn cools the cows—unlike sprinkler systems (generally used in more humid climates) that directly wet and cool the cows’ hides (11).

Results of a recent Ohio State University study suggest that, based on net

return, a combination of fan and sprinkler set-up is the best cooling system

for producers across most of the United States (12).

Several companies offer stir fans that oscillate in order to increase the effective cooling area. One of note (13) uses a special controller to program the movement of a bank of stir fans to track along with the movement of shaded areas as their location changes with sun position over the course of a day. In this way, cows are always befitting from the combined cooling effect of the shade and the air movement. Fog or mist systems are often combined with stirring fans in order to increase the efficiency of the evaporative process. Combination fog/stir-fan systems are available from several manufacturers. |

|||

.

| References | ||

| 1 | Managing and Feeding Lactating Cows in Hot Weather (GA) | |

| 2 | Balancing Diets for Dairy Cattle During Heat Stress Conditions | |

| 3 | Management Considerations for the Dairy Cow During Heat Stress (NC) | |

| 4 | Drought Strategies for Dairy Producers (TX) | |

| 5 | Economics of Heat Stress (FL) | |

| 6 | Reducing Heat Stress for Dairy Cattle (VA) | |

| 7 | Accounting for wind speed and solar radiation in the THI, (proceedings, pg 2) | |

| 8 | Reducing Heat Stress (MS) | |

| 9 | Pro-Dairy Website | |

| 10 | Design of HVLS Fan Supplemental Cooling System in Dairy Free Stall Barns | |

| 11 | Micro-sprinkler and Fan Cooling for Dairy Cows.... (KY) | |

| 12 | Heat Stress Costs US Livestock Producers Billions (OH) | |

| 13 | Advanced Dairy Systems, Phoenix, AZ Tel (602) 254-5488 | |

| More Web-Based Info on Dairy Heat Stress Click Here | ||

----------------------------------------------------------

| Dr. Jim McFarlane is founder and president of Animal Environment Specialists, an independent consulting firm serving the livestock production industry since 1987. Experts in environmental management, we help pork, poultry, dairy, and veal producers create healthy, stress-free environments to maximize animal health and productive performance. We assist in troubleshooting environmental problems, planning new facilities, remodeling old units, and provide advice on how to best manage livestock environments day-in, day-out. Animal Environment Specialists offers a variety of hand-held measuring and monitoring devices –-selected specifically for use in livestock facilities—at our website, MeterMall.com. | ||

| . | ||

|

Animal | |

| Environment | ||

| Specialists, Inc | ||

| 11951 Rausch Rd * Marysville, OH 43040 | ||

| Tel +937-642-4691 * Fax +937-642-4691 | ||

.....

.....